Discover our expertise : About us

Committed to a sustainable approach, we support the Agro-industry and Civil Engineering sectors by providing innovative and environmentally friendly solutions. In particular, our coatings, designed for Building and Industry, are bio-based and solvent-free. As a result, they ensure optimal protection while also minimizing environmental impact.

Our resins are qualified by the CSTB (Technical Approval and Technical Document) which ensures their reliability and performance. Moreover they meet the requirements of infrastructure related to hygiene, particularly in the prevention of bacterial contamination. In addition they are certified for water-related environments (ACS certification) as well as the agri-food industry, where they provide anti-corrosion protection of tanks and silos. Finally our products comply with fire resistance and decontaminability standards required in the nuclear industry.

An impenetrable barrier against water, providing long-lasting protection for your facilities with our waterproofing resins.

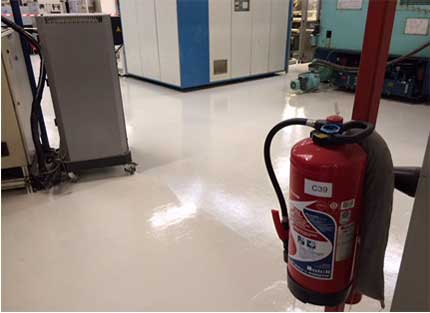

Maximum safety with our fire-resistant waterproofing resins, designed to prevent fire hazards.

Discover some coating projects using our polyurethane resins by our certified applicator partners.

Make sure the surface to be treated and the tools used are clean, dry, and free from any dirt, grease, or debris. Clean them thoroughly if necessary.

First, homogenize the polyol, then mix the polyol (base) and the isocyanate (hardener) for about 40 seconds. DPU ~40 min.

Application of the resin in two ways: with a roller or a notched trowel.

Drying time of approximately 12 hours varies depending on temperature and humidity (see Technical Data Sheets).

Nous utilisons des cookies pour vous offrir la meilleure expérience sur notre site.